1. Preparing the plates

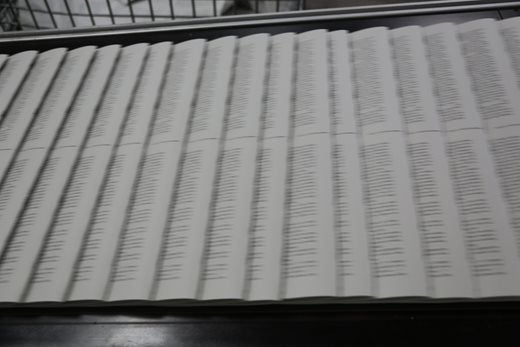

Before printing can take place, metal printing plates of the book must be prepared. Rubber is burnt onto each plate, leaving behind a text image of the book.

Originally, the text was made up of individual pieces of metal type assembled page-by-page, rather than being lasered onto a plate digitally – an immensely skilled and painstaking process. Advances in printing technology to what we have today have enabled the production of affordable and mass market books and revolutionised the dissemination of knowledge and art.

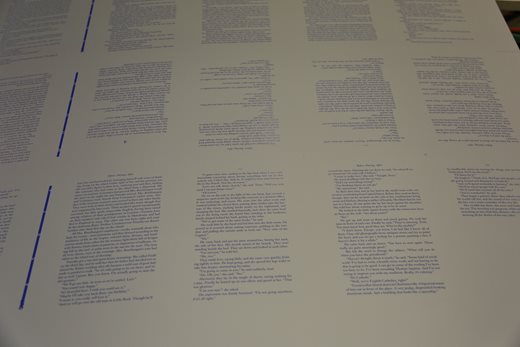

Every printing press has its own specifications that determine how many pages can be produced on a single plate: it’s usually sixteen, but it can be eight, thirty-two, etc. The number of pages must be a multiple of this figure, which is why you’ll sometimes see blank pages at the beginning or end of books. A 1000 page book, for example, can be broken down into sixty-three sixteen page sections with eight blank pages.